The flexible bending machine, a new - generation automated apparatus, is meticulously designed for the precise bending of plates and thin - sheet metals. By harnessing advanced CNC programming technology, a robotic arm autonomously executes bending tasks. An integrated induction device continuously monitors material parameters such as thickness, type, and hardness in real - time. This allows for automatic adjustments, ensuring that each bend meets the highest accuracy standards

The gradual replacement of ordinary bending machines by intelligent flexible bending centers is the result of the comprehensive effect of multiple factors. The following aspects will be explored from the dimensions of technology, market, production efficiency, and cost control

The main advantages of the intelligent flexible bending center compared with the traditional bending machine are as follows:

Speed

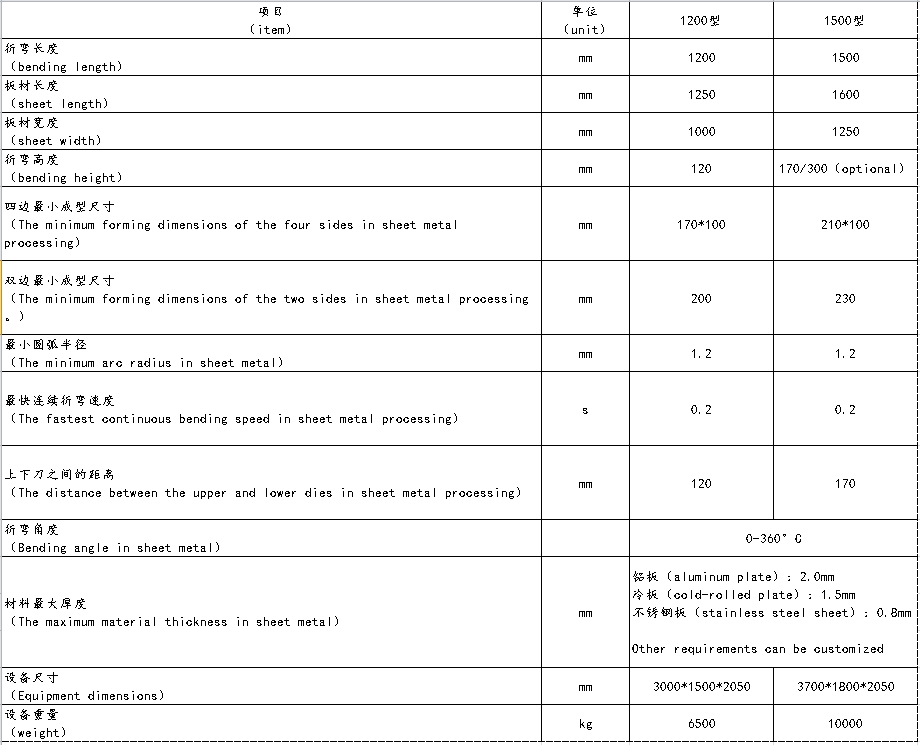

The bending process of the intelligent flexible bending center is completely automated, and the fastest speed can reach 0.2 seconds per bending stroke, which greatly reduces the cycle time for multi-sided and multi-pass bending. It is more than three times faster than the traditional CNC bending machine. The more folds and the more complex the workpiece, the greater the speed advantage.

The traditional CNC bending machine requires skilled workers to hold the workpiece for positioning and bending. Each bending edge requires repositioning, resulting in relatively low efficiency.

Labor

The intelligent flexible bending center has low technical requirements for workers. Ordinary workers can take up their posts after training, and there is no need to hire experienced skilled workers. At the same time, the bending process is completely automated, which greatly saves labor and significantly reduces the labor intensity of workers. For workpieces with larger dimensions on the traditional CNC bending machine, it often requires multiple people to complete the operation. However, for the intelligent flexible bending center, workers only need to place the workpiece on the workbench, and the equipment will automatically complete the positioning, which is truly time-saving and labor-saving.

Safety

The intelligent flexible bending center does not require workers to hold the workpiece manually. The bending process is completely automated, which greatly reduces the potential safety hazards caused by workers' misoperations.

Ease of Use

The intelligent flexible bending center adopts graphic visual programming. Workers only need to input the bending data according to the workpiece, and the system will automatically generate bending instructions without the need for code programming. Ordinary workers can master it within 2 hours. The traditional CNC bending center requires workers to master complex programming skills and remember the bending sequence of each bending edge during the bending process, which is difficult and has a high error rate.

Consistency

The intelligent flexible bending center can achieve automatic positioning of the sheet metal. The system has a high positioning accuracy, and the formed products have higher consistency, making it more suitable for mass production. The traditional CNC bending center has a relatively low positioning accuracy, and there will be dimensional errors caused by multiple positionings.

Automation

The intelligent flexible bending center has reserved a wealth of interfaces, making it convenient to connect to the upstream and downstream production lines. It can be connected to a robotic arm to achieve automatic integrated loading and unloading. When equipped with a self-driven robotic arm that shares the same control system with the intelligent flexible bending center, the synergy efficiency is higher. When changing workpieces, there is no need to maintain two sets of programs. Only the program of the bending center needs to be changed, and the program of the robotic arm will be automatically generated, which has higher flexibility.

There are various reasons why the intelligent flexible bending center is gradually replacing the ordinary bending machine. It not only has significant advantages at the technical level but also can better meet market demands, improve production efficiency, and reduce production costs. This transformation is not only an inevitable result of technological development but also a reflection of changes in market demands and the production environment. In the future, with the continuous development of the manufacturing industry and the continuous progress of technology, the application scope of the intelligent flexible bending center will be further expanded, and its position in the manufacturing industry will become more stable. At the same time, this will also drive the entire manufacturing industry to develop in a more efficient, intelligent, and green direction.