一、The machine adopts an integral welding structure, with the frame consisting of left/right wall panels, workbench, fuel tank, braces, synchronous shaft, and sliding block.

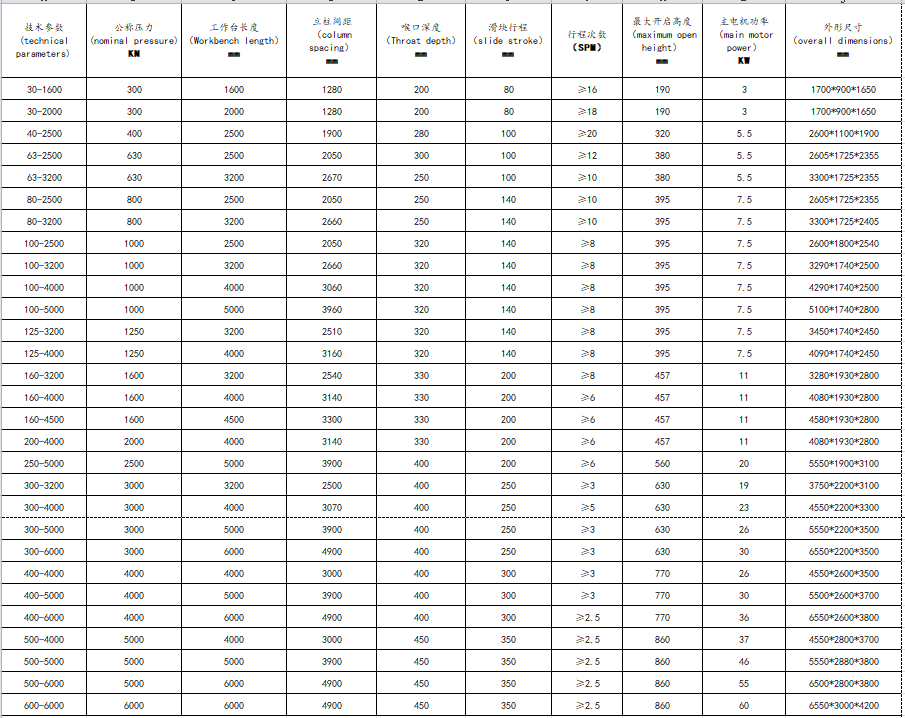

二、technical parameters

三、The part of the equipment frame

The frame is formed by welding workpieces such as left and right columns, oil tank and braces into an integral framework, and the workbench is firmly connected to the lower parts of the left and right columns

四、slider part.

The slider part consists of a slider, oil cylinders, and a fine - adjustment structure for the mechanical stop, etc. The slider adopts an integral panel structure. The left and right oil cylinders are fixed on the frame. Through hydraulic pressure, the piston (rod) drives the slider to move up and down,The mechanical stops are externally installed on the tops of the two oil cylinders. They feature a compact structure and can be synchronously adjusted on both sides. When the left and right sides of the slider (upper die) are at different heights, stop the slider at the top dead center. Disengage the coupling sleeves of the synchronous transmission shafts on both sides of the mechanical stops. Rotate the worm on either side of the worm gear boxes on the upper parts of the left and right oil cylinders (clockwise or counter - clockwise). Then press the slider to the bottom dead center, measure the height and make adjustments (repeat the above operations) until the left and right sides of the slider (upper die) are at the same height. Finally, position and install the coupling sleeves

五、synchronization mechanism

The mechanical forced synchronization mechanism composed of a torsion shaft and arms features a simple structure, stable and reliable performance, and high synchronization accuracy

六、Rear material stop mechanism

It is controlled by the button box in front of the workbench. The motor drives the material stop rack to move back and forth, and the moving distance is digitally displayed with a minimum reading of 0.10 mm. (There are travel switches for limit control at both the front and rear positions). The ejector rod on the rear material stop can rotate around its axis to prevent damage to the workpiece during bending. It is convenient and fast to operate, and has high material stop accuracy.

七、Precision compensation mechanism for bent workpieces

The fine - adjustment mechanism is installed on the upper die and is used for fine - tuning the vertical compensation of the upper die to ensure the precision of the bent workpieces. Sometimes, there is a slight deviation in the angle of the bent workpiece along its full length. To achieve better consistency in the bending angle, you can slightly loosen the die tightening screws (be careful to prevent the upper die from falling off and damaging the die), move the wedge block left or right to perform fine - tuning of the upper die vertically, then tighten the screws and try bending again until the satisfactory requirements are met

八、Machine tool electrical system

Main power supply: 380V, 50Hz, three - phase; Control power supply: 220V. Automatic switches are used for short - circuit protection and overload protection of the main circuit and each motor. Fuses are used for short - circuit protection in the control circuit part. All the main components of the machine are reliably grounded、This machine has three working modes. You can use the universal change - over switch to select jogging, single - cycle, or continuous operation. The machine is operated via a foot switch, which is convenient and fast. This machine is equipped with indicator lights for the power supply and the machine's working status. Siemens electrical components are used. The circuit is simple, safe, and easy to maintain

九、Machine tool hydraulic system

The hydraulic system consists of a motor, an axial piston pump, a valve block, an oil tank, oil pipes, and hydraulic accessories. The maximum working pressure of the hydraulic system is 20 MPa, which is set by the main circuit system valve. The hydraulic valves are selected from Shanghai - made ones, and all the seals are from Japan's Valqua. The pipeline layout is simple, with less leakage and is convenient for maintenance and debugging